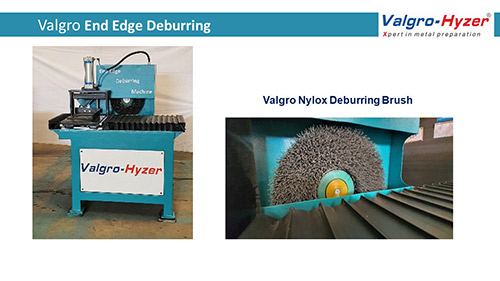

Valgro End edge deburring machine works to deburr round, rectangular, square, and other shape's edges. It is also compatible with many different cut tube and profile shapes and delivers results in a few seconds and in a single operation. The deburring operation can be done simultaneously inside and outside of the tube in a single operation without rotating the tube. The process result is the elimination of burrs getting slightly rounded edges. It can be integrated with a single Head Semi-Automatic End Edge Deburring System. Its automatic clamp shell hood provides added safety and additional dust control.

-

Overview

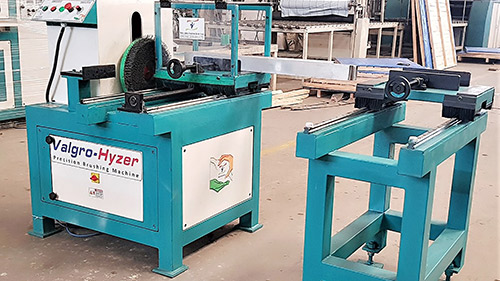

Valgro India offer flat sheet / Flat bar side grinding machine. Made for stainless steel bars and plates side polishing and deburring on this video it is demonstrated side grinding with 100mm width 10mm thick Flat sheet.

-

Features

Features

- Pneumatic brush head movement

- Multiple disc brushes with 12 and 14 inches

- 2HP motor and variable speed drive

- Custom clamping for adjusting lengths

- Three to four cycles per minute

- Compatible with table extension

- Brush diameter can range up to 400mm

- Full cover boy for dust protection

- Dust collection unit: DS3

- Table movement length can range up to 600mm

Advantage compared to the traditional deburring process

- Avoid unhealthy position compared to the traditional operation

- No Physical Strain of worker by vibrations and flying spark,

- Employee do not suffer under flying spark, dust, and noise.

- Unskilled labor run this machine

- Save money and time by less down time

-

Technicality

Model EED14-M EED14 A EED14BE Head Type Wheel / Disc Wheel / Disc Wheel / Disc Work Surface End Edge End Edge End Edge - Both Side Work Head 1 1 2 Process: Wet / Dry Dry Dry Dry Application Burr Removal Inside + OutSide Finish Achieved Smooth edge Smooth edge Smooth edge Type of Material Cut Part Cut Part Cut Part Burr Classification Class #1 & Class #2 Max Dia 100 100 100 Min. Length 200 200 200-600 Brush Diameter 300 / 350 300 / 350 300 / 350 Brush Action R = Rotate / O = Oscillate R R+O R+O Conveyor Type R= Roller / B = Belt Manual Belt Belt Conveyor speed Min / Max - MPM Manual Feed 0.5 - 10 0.5 - 10 Dust Extraction : Valgro-Duklean DCS-1 DCS-3 DCS-5 Electrical parameters The integrated frequency converter allows the machine to work worldwide with all power supply systems and enables smooth start and enhanced motor protection.

All Dimensions in MM -

Applicatons

- Aluminum extrusions saw cut profile for automotive, aerospace, building construction, and medical device industries.

- Cut Tube, Pipe deburring

- Valgro Abrasive nylon brushes are an excellent tool for deburring and Edge Radiusing

-

Gallery